E-mail:13905210686@153.com

E-mail:13905210686@153.com

Tel:+86-13905210686

Tel:+86-13905210686

E-mail:13905210686@153.com

E-mail:13905210686@153.com

Tel:+86-13905210686

Tel:+86-13905210686

Solution

If you are interested in our services or products, you can contact us directly. We look forward to collaborating with you!Interlocking piles refer to a form of foundation pit retaining structure in which mechanical drilling, wall protection, soil extraction, and cast-in-place concrete pouring are used to form piles, with the piles interlocking (intersecting) with each other and arranged. Interlocking posts are divided into hard interlocking posts and soft interlocking posts.

◆ Advantages of hard cutting of interlocking piles:

(01) It avoids the occurrence of adjacent hole concrete pipe gushing phenomenon that is prone to occur when the ultra-retarded concrete interlocking piles are cut and interlocked. At the same time, due to the use of conventional concrete, the requirements for concrete are reduced, and costs are saved.

(02) Due to the adoption of hard cutting technology, there will be no drawback that the concrete strength of pile A is too high due to the excessively long pile formation time, making it impossible to carry out the interlocking construction of Pile B.

(03) When encountering large underground obstacles that are relatively hard, the full-rotation drilling rig can directly clear underground rock layers and obstacles during the pile formation process, achieving pile formation in one go.

(04) The full-casing full-rotation drilling rig itself has the function of water-stopping and wall protection during construction, and no additional wall protection measures are required. It is an energy-saving and environmentally friendly construction process.

(05) According to the depth of soil extraction by the grab, the soil layer can be accurately distinguished, and the appropriate bearing stratum at the pile end can be selected.

(06) The soil taken from the hole has a relatively low moisture content, which is convenient for transportation outside and there is no concern about mud polluting the environment. The construction site is clean and civilized, making it extremely suitable for construction within the urban area.

(07) It is easy to control settlement and displacement, and can be used for construction close to nearby buildings and underground pipelines.

(08) The full-rotation pipe following drilling and other tunneling methods effectively prevent sand and mud gushing in the hole and allow for rock embedding, ensuring the quality of pile formation.

(09) For the second construction, the piles were cut and interlocked between the two piles that had been completed in the first construction. The full casing protection hole method ensured the tight interlocking between the piles, and the pile concrete solidified into one, forming a good overall continuous structure.

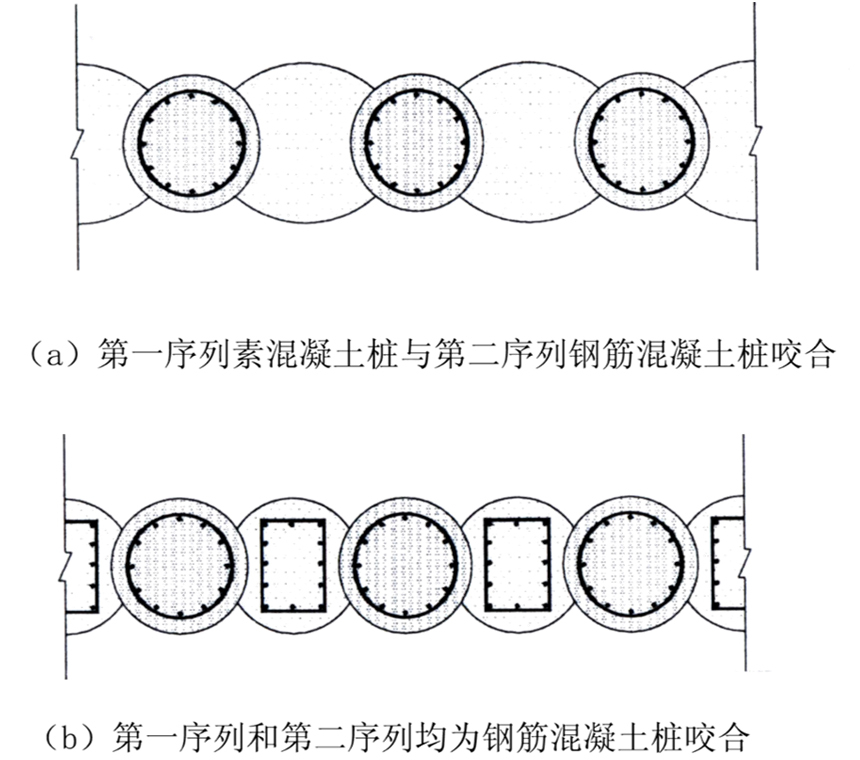

(10) The reinforcement ratio is relatively low, which is because the bored interlocking piles can adopt the arrangement of reinforced concrete piles and plain concrete piles at intervals.

(11) It has a stronger anti-seepage capacity. This is because the bored interlocking piles are continuously constructed, and there are no construction joints between the piles. However, the construction joints at the split joints of underground continuous walls are often the weak links in anti-seepage.

(12) The construction is flexible. This is because during the construction of the bored interlocking pile, it can be turned and changed as needed, making it more suitable for the construction of some foundation pits with variable planar geometric shapes or various arcs.

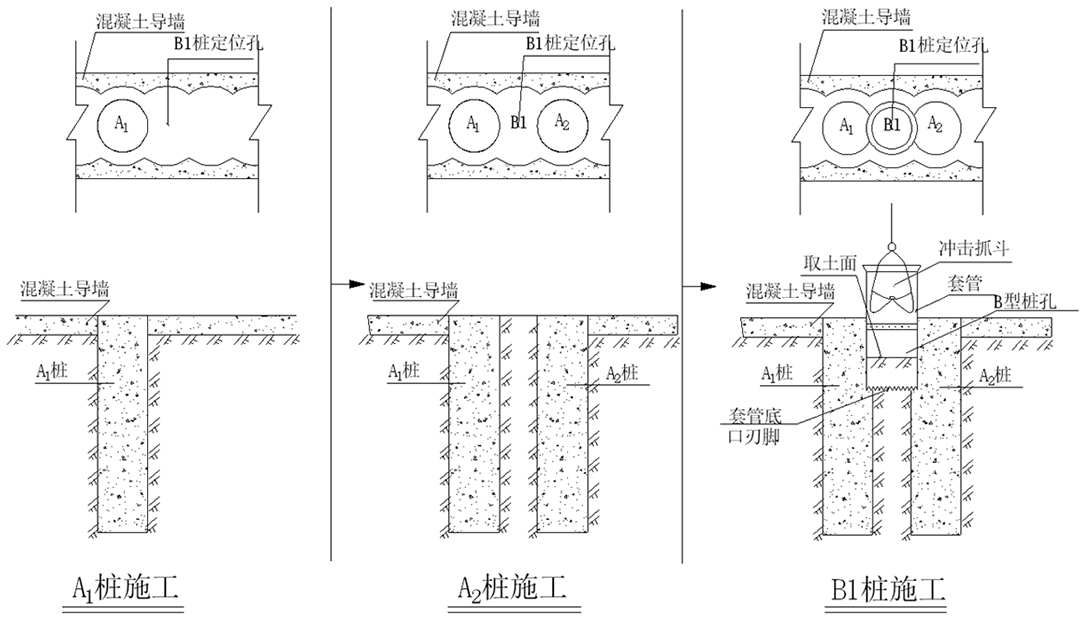

◆ Schematic diagram of the construction technology of interlocking piles:

◆ The form of the steel cage in single-pile construction:

◆ Key points of construction:

Determination of the interlocking thickness of the bored interlocking pile and the requirements for verticality

The interlocking thickness d between adjacent piles is selected based on the pile length. The shorter the pile, the smaller the interlocking thickness (but the minimum should not be less than 100mm), and the longer the pile, the greater the interlocking thickness.

Calculate according to the following formula: d-2 (kl+q) ≥50mm

In the formula

l - Pile length

k - Verticality of the pile

q - Allowable value of orifice positioning error;

d - The designed interlocking thickness of the drilled interlocking pile;

The significance of the above formula lies in ensuring that the minimum designed interlocking thickness of the pile bottom is not less than 50mm.

Take a pile length of 30m(i.e. 3000mm) and a interlocking thickness of 20cm(i.e. 200mm) as an example:

200mm-2 (1/500*3000mm+10mm) =60mm is greater than 50mm

◆ Fuzhou Underground Parking Garage Enclosure Structure - Circular interlocking piles:

◆ Guarantee of verticality:

◆ Common problems of interlocking piles in other construction methods:

◆ Case:

The intercity railway from Hangzhou to Fuyang is 23 kilometers long and has 11 stations, all of which are underground. The retaining structures of the underground stations all use interlocking piles, totaling 600,000 meters